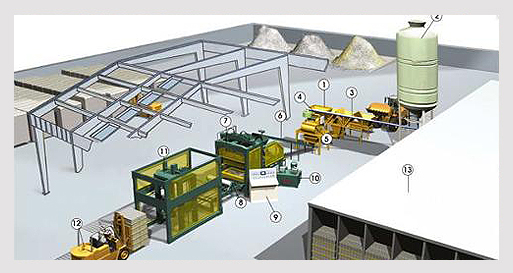

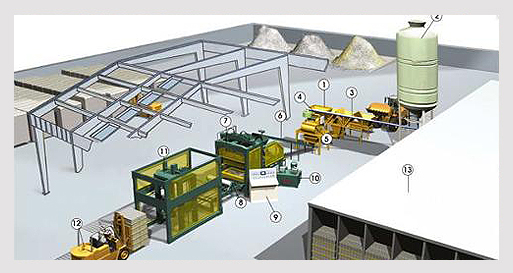

1. Aggregate bunker

2. Cement silo

3. Batching machine

4. Cement measuring unit

5. Concrete Mixer

6. Concrete belt conveyer

7. Block making machine (Main machine)

|

8. Block conveyer

9. Control system

10. Hydraulic station

11. Automatic elevator

12. Forklift cart

13. Curing room (prepared by customer)

|

Descriptions of Semi-automatic Block Production Line(Brick machine):

1. The semi-automatic production line equipped with QT series block making machine.

2. Aggregate, fine material can be measured, conveyed, lifted automatically. Instant and accurate in batching, guarantee the matching and quality, and improve the quality of product.

3. It is a semi-automatic production line, some operation stages are manual operation such as nature maintenance.

4. Compared with full-automatic production line, the semi-automatic production, simpler in production, lower requirement on worker technical skill, less production cost and energy consumption. Due to nature maintenance, influenced by climatic conditions, output is relatively lower than full-automatic one.

5. Production Capacity depends on the main machine the line adopt.