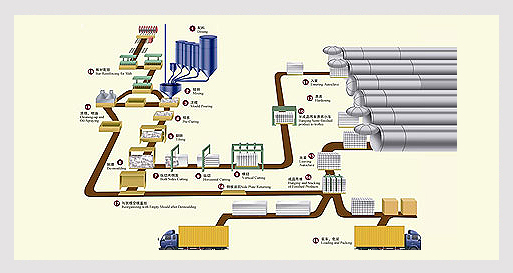

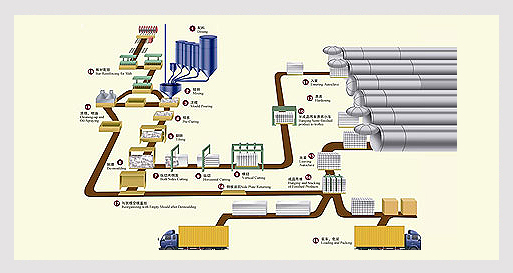

AAC Lightweight Block Production Line

As a new building material, AAC lightweight block production line fulfills the demand of concrete industry, which requires to save the natural resources and protect the environment.Queen Machinery Co.,Ltd's AAC lightweight block making plant can meet the specific requirements of the market and customers.

AAC is environment-friendly and new building material. AAC has the advantages of extremely light weight, high compressive strength, excellent thermal insulation, great acoustic insulation and high fire resistance. AAC is produced out of a mix of cement, lime, fly ash, gangue, river sand and aluminium powder etc., through batching, mixing, casting, cutting and autoclaving. AAC can be produced in a large variety of sizes, from stand blocks to large reinforced panels, and it can be cut, sawn, drilled, nailed and milled like wood, making it an extremely workable product.