QT12-15 Automatic Brick Making Machine

1.QT12-15 automatic block making machine has the production output of 17280-23040 blocks (400×200×200mm) for one day (8 working hours).

-- 12 stands for the production quantity is 12 blocks "400×200×200mm" per mould;

-- 15 stands for the cycle time is 15 seconds

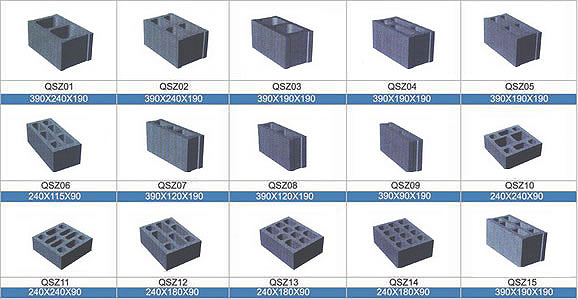

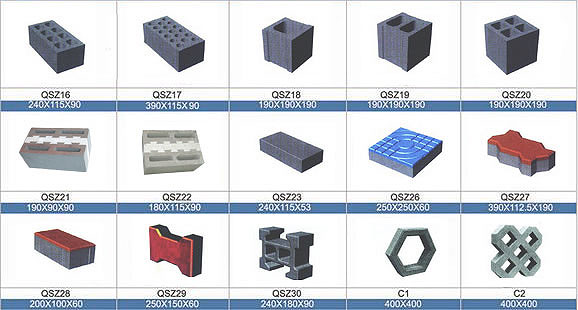

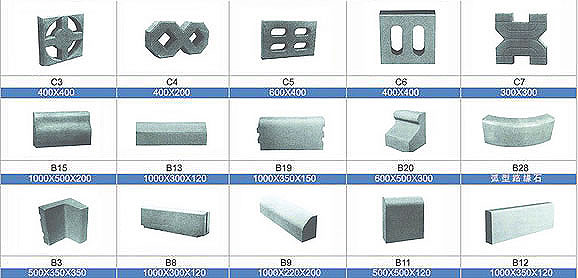

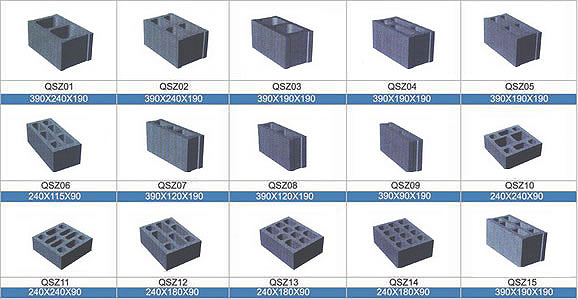

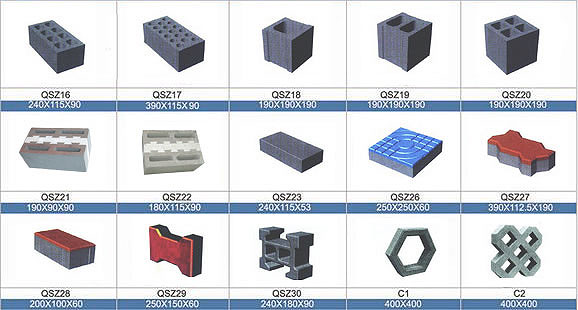

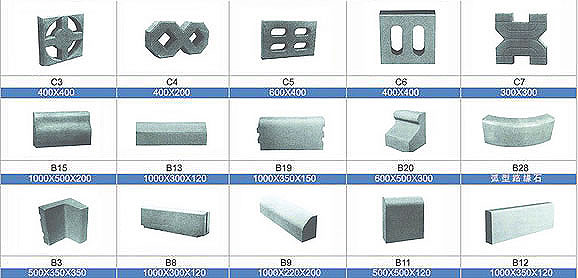

2. As the moulds are changeable, QT12-15 is able to produce various types of hollow blocks, solid bricks, interlocks, pavers and curbstones, etc.

Main Technical Specifications of QT12-15 Automatic Brick Making Machine:

| Production per Mould |

12 pcs/mould (Standard Block: 400×200×200mm) |

| 60 pcs/mould (Solid Block: 240×115×53mm) |

| 35 pcs/mould (Hollow Block: 240×115×90mm) |

| 48 pcs/mould (Holland Brick: 200×100×60-80mm) |

| Cycle Time |

15-20 seconds |

| Production per Day (8 Working Hours) |

Hollow Block (400×200×200mm): 17280-23040 pcs |

| Solid Block (240×115×53mm): 80640-115200 pcs |

| Hollow Block (240×115×90mm): 50400–67200 pcs |

| Holland Brick (200×100×60-80mm): 55296–69120 pcs |

| Vibrating Frequency |

2940 rolls/minute or 50-65 HZ |

| Vibrating Force |

160 KN |

| Motors Power |

64 KW |

| Machine Dimensions |

9100×4800×3170mm |

| Pallet Size |

1400×1000×30mm |

| Gross Weight |

about 15T |

| Raw Materials |

Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Applicable Products |

concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applicable Fields |

widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

Block and Brick Models