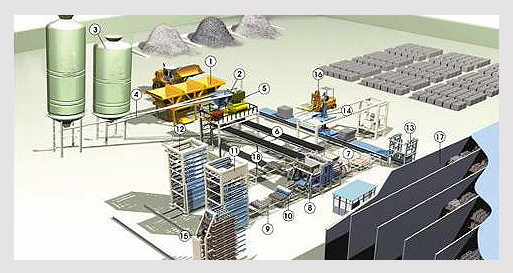

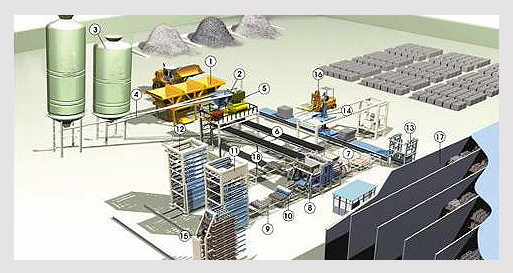

1. Batching machine

2. Concrete Mixer

3. Cement silo

4. Cement screw conveyer

5. Cement measuring unit

6. Concrete conveyer

|

7. Pallet conveyer

8. Block making machine (Main machine)

9. Block conveyer

10. Block cleaner

11. Elevator

12. Lowerator

|

13. Stacker storing unit

14. Cuber

15. Finger Cart

16. Forklift cart

17. Curing room (prepared by customer)

|

Descriptions of Fully Automatic Block Production Line:

1. Modularized Production Line: Base on QT6/8/10/12 block making machines as main machine. It can form production line with single or double main machines.

2. Advanced Technology: Adopt advanced technology, combine with ten years experiences, developing and innovating.

3. Advanced Performance: Widely used, steady and reliable quality, convenient to operate and maintain.

4. Intelligantize Integration Control System: Through network or center assemble line to transmit data, Monitor And Control every part with quick, accuracy, real time characteristic, fault alarm, can finish telenet visit, make the manufacture factories easy to adjust program, set the parameter, amend and upgrade system.

5. Top Brand Parts and Components: Adopt the international famous Mitsubishi PLC and transducer, Omron sensor, guarantee the dependability and stability of the whole production line to operate continuously with two shifts one day.

6. Production Capacity depends on the main machine the line adopt.