Wet Pan Mill, also known as a Round Mill, is a widely used grinding and amalgamation machine designed primarily for gold ore processing. It is particularly popular in small and medium-scale mining operations due to its low investment cost, easy operation, and high recovery rate.

How It Works

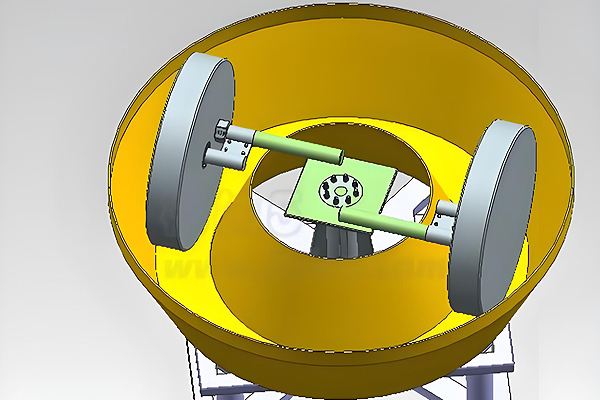

The wet pan mill operates on a simple mechanism:

1. Crushed gold ore, water, and sometimes mercury or other chemicals are placed into a rotating circular pan.

2. Two heavy grinding rollers rotate and crush the materials against the bottom and sides of the pan.

3. Through this process, the valuable gold particles are released from surrounding rock and concentrated in the pan.

This traditional grinding method is effective for grinding, crushing, mixing, and amalgamating soft or semi-hard ores—especially suitable for free-milling gold.

Key Advantages

✅ High Gold Recovery Rate

Wet pan mills can extract more than 90% of the gold in suitable ores, especially in regions where free gold is present.

✅ Low Energy Consumption

Operates efficiently with minimal power compared to ball mills and other crushing equipment.

✅ Simple Structure, Easy Maintenance

Easy to operate and maintain, ideal for remote mining areas with limited technical support.

✅ Low Investment, Fast Returns

Perfect for small-scale miners looking to achieve quick profits with minimal startup costs.

Common Applications

1. Gold ore grinding and amalgamation

2. Beneficiation of iron, molybdenum, lead, zinc, antimony, and other ores

3. Material mixing in brick and cement industries (in some regions)

Popular Models

| Model | Roller Diameter (mm) | Capacity (t/h) | Power (kW) |

|---|---|---|---|

| 1100 | 1100 | 0.5 – 1.2 | 5.5 – 7.5 |

| 1200 | 1200 | 1 – 1.5 | 7.5 – 11 |

| 1400 | 1400 | 1.5 – 2.5 | 11 – 15 |

Note: Output varies depending on material hardness and feeding size.

Widely Used in Africa, South America, and Southeast Asia

Thanks to its affordability and reliable performance, the wet pan mill is a favorite in gold mining communities across countries such as Sudan, Zimbabwe, DR Congo, Peru, Bolivia, and the Philippines.

Conclusion

The Wet Pan Mill remains a practical and powerful solution for small-scale gold recovery. Whether you’re a local miner or a mining equipment distributor, investing in wet pan mills can provide efficient, cost-effective, and high-yield results in gold processing.