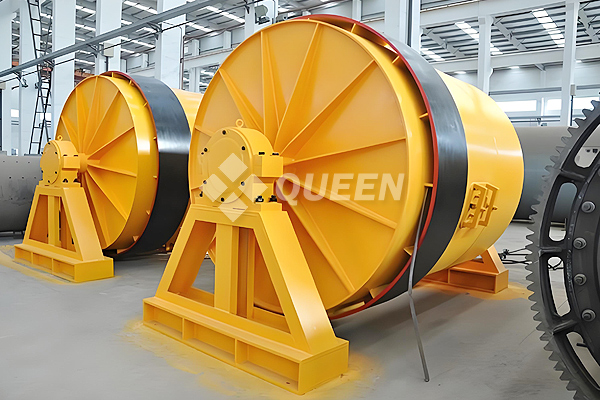

What is a Ceramic Ball Mill?

Ceramic ball mill is a specialized grinding machine designed for fine grinding of materials. Unlike conventional steel ball mills, it uses ceramic liners and ceramic grinding media (such as alumina balls or zirconia balls). This design ensures no iron contamination, excellent wear resistance, and lower energy consumption, making it ideal for industries with strict purity requirements, such as ceramics, glass, chemicals, pharmaceuticals, and food.

Working Principle of Ceramic Ball Mill

The working principle of a ceramic ball mill is similar to that of a traditional ball mill:

The motor drives the cylinder to rotate;

Ceramic grinding media inside the cylinder are lifted and dropped;

The material is crushed and ground through impact and friction;

Finally, fine and uniform powder is obtained.

Since both the cylinder and grinding media are made of ceramic materials, no metallic impurities are introduced during the process, making it highly suitable for high-purity material grinding.

Key Advantages of Ceramic Ball Mill

1. Contamination-free: Ensures product purity by avoiding iron impurities.

2. High wear resistance: Durable ceramic liners and media extend service life and reduce maintenance costs.

3. Energy-efficient: Smooth operation with lower energy consumption.

4. Wide applicability: Suitable for both wet and dry grinding of various non-metallic minerals and chemical materials.

5. Adjustable fineness: Delivers fine grinding results with flexible particle size control.

Applications of Ceramic ball mills

1. Ceramic industry: Grinding of glaze materials and body materials.

2. Glass industry: Processing of high-purity quartz and glass raw materials.

3. Chemical industry: Grinding of alumina, zirconia, silicates, and other powders.

4. Pharmaceutical & food industries: Suitable for hygienic and high-purity material grinding.

How to Choose the Right Ceramic Ball Mill

The configuration of a ceramic ball mill depends on several factors:

1. Type of material (hardness, purity requirements);

2. Production capacity (daily output);

3. Grinding method (wet or dry grinding);

4. Fineness requirements (desired final particle size).

Therefore, the price of a ceramic ball mill is depends on the characteristics of the raw material, process requirements, and production capacity.