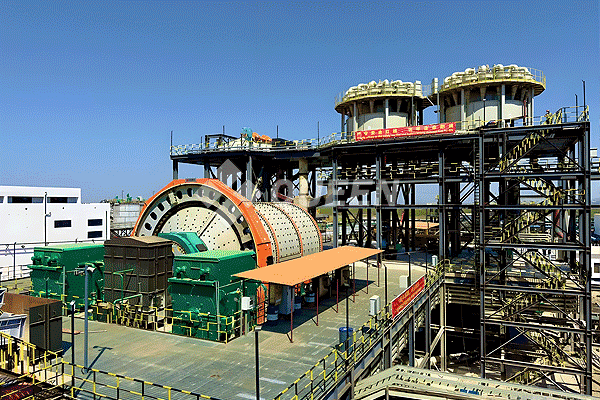

What is a Wet Ball Mill?

Wet grinding refers to the process where ore, after entering the mill, is crushed through the interaction of grinding media and the ore itself, with water flow playing a role in the ore’s movement. During this process, water is added to help facilitate the grinding. The ball mill used for wet grinding is called a wet ball mill. Depending on the motion characteristics, wet ball mills can be categorized into simple swing type, complex swing type, and hybrid swing type.

Working Principle of Wet Ball Mill

The working principle of a wet ball mill is similar to the dry grinding method, with the key difference being the addition of liquid medium during the grinding process. Proper control of the grinding concentration is essential. The amount of water added generally depends on the intended use of the slurry, the amount of clay in the mixture, and the clay’s water absorption value. The material is progressively crushed under the impact and grinding action. The ground ore is discharged through the discharge section. The discharged material is classified in a spiral classifier, and the qualified product is separated. Coarse sand is sent back to the ball mill for further grinding via a combined feeder. The feed system continuously and evenly feeds the ore into the ball mill, and the ground material is constantly discharged from the mill.

Advantages of Wet Ball Mill

1. Wet ball mills offer superior performance, higher grinding efficiency, and can process ores with low water content, as well as ores with high moisture and clay content.

2. Wet ball mills require fewer auxiliary devices and have simpler material transportation systems, leading to 5%-10% lower investment costs compared to dry ball mills.

3. Wet grinding not only reduces agglomerated materials into fine particles (usually rounded particles, though not typically cleaved ones) but also forces the mixing of barren and plastic materials, ensuring a uniform blend.