What is dry ball mill?

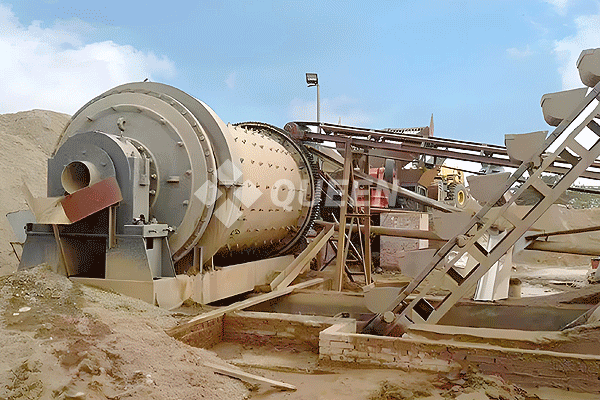

Dry Grinding is a mineral processing method where the material, after being crushed inside a ball mill, is drawn out of the mill by air flow when it reaches the desired particle size. During the dry grinding process, the equipment used is a dry ball mill, which operates without the addition of water. Therefore, the material must remain dry. The dry ball mill is cylindrical in shape and is equipped with an air suction device, dust removal pipes, and dust collectors. It plays an important “grinding” role in the beneficiation of various minerals.

Working Principle of Dry Ball Mill

The dry ball mill is a cylindrical rotating device that uses an external gear for transmission. It typically features a two-compartment structure and is usually a lattice type ball mill. The material enters the first compartment of the mill through the feeding device and is evenly distributed by a hollow shaft screw. Inside the first compartment, there are stepped or corrugated liners and different-sized steel balls. When the cylinder rotates, centrifugal force lifts the steel balls to a certain height, causing them to fall and impact the material, thus performing coarse grinding. After coarse grinding, the material passes through a single-layer partition into the second compartment, where flat liners and steel balls further grind the material into a powder. Finally, the ground material is discharged through a discharge grate, completing the grinding process.

Advantages of Dry Ball Mill

1. Smooth Discharge: The dry ball mill adopts a grate discharge method, ensuring smooth material discharge and preventing overgrinding. The cylinder does not require cooling, offering long service life and low failure rates.

2. Energy Efficiency: The device is equipped with various auxiliary components, improving the traditional mill structure. The machine body and base frame are integrated, allowing for easy installation by directly lifting onto the foundation. In addition, the main bearing uses double-row radial spherical roller bearings, which significantly reduce energy consumption by approximately 30%.